Exactly what is the value add for label printing companies that are adopting or purchasing hybrid presses that can do a combination of processes such as flexo and digital in one pass to accommodate their customers?

Is it the right time for labels manufacturers to integrate all things digital? Flexo printing has been around for decades and is considered the standard for printing labels.

Is it the right time for labels manufacturers to integrate all things digital? Flexo printing has been around for decades and is considered the standard for printing labels.

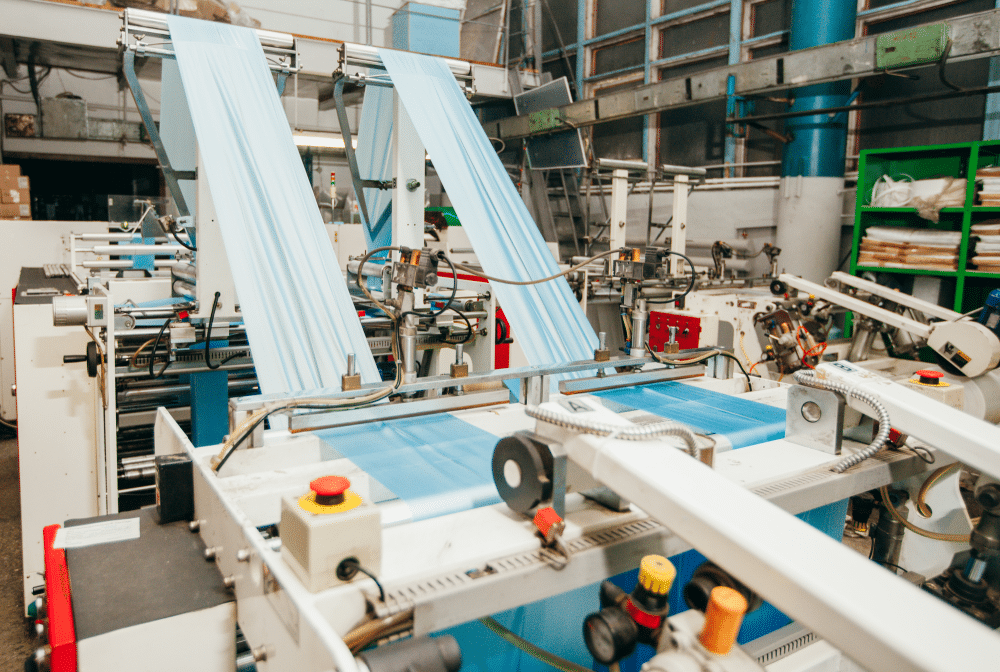

Flexo and digital are not competing technologies; rather can integrate as a hybrid. When one version of a label is printed and completed, it then takes additional time and labor to complete the setup for the next job to print—changing colors, plates, etc. And during that downtime, when the press is not running, the label printer/converter is not making money. So longer runs with minimal changes are best for flexo.

So, when does one use digital? It is ideal for a short run and jobs that require multiple versions and SKUS, and when one requires consistency in production with computerized color management. The advantage of digital over flexo is the setup downtime, cost of inventory and material is lower. Therefore, digital printing provides an efficient way to handle short to medium run lengths, while providing the flexibility to finish inline or near line. From an efficiency standpoint, many label printers and converters are looking at digital to complement their flexo label printing business.

Hybrid Presses Market Growth

Label printers know that having digital in their production environment compliments their flexo business from both a capacity standpoint and expanding their customer base. LPC reported in 2016 that 10% of labels printed in North America were printed digitally, and there were 130-140 digital production presses sold and the fastest growing market will be in the digital / hybrid market growth so that by 2020 3 of every 4 presses sold will be digital.

The term “hybrid production environment” denotes plants that can print both flexo and digitally. Consider that of the top 400 printers in North America, whose service offerings include combinations of digital web, cut-sheet, wide and grand-format, and hybrid offset / digital printing, only 12 of them are all digital. So, as you can see the common denominator is, they use both flexo and digital processes. These are hybrid presses.

So, what exactly is all the excitement about hybrid presses?

Both flexo and digital press manufacturers are working hard to associate themselves with the concept of hybrid presses printing, often creating extensive marketing campaigns to show how their “hybrid” is superior to others.

Imagine integrating the best of flexography, digital, and screen-printing on one custom label. Now, imagine all these capabilities on one press and executed in one pass. The top producing executive recruiter in pressure sensitive labels and flexible packaging is The Marathon Group for over 30 years. Have a need to recruit a Mark Andy, Nilpeter or digital press operator, VP Sales, Quality Manager or Plant Manager? Call Michael Moore at 904-270-2121 or email [email protected]